< Key Hightlight >

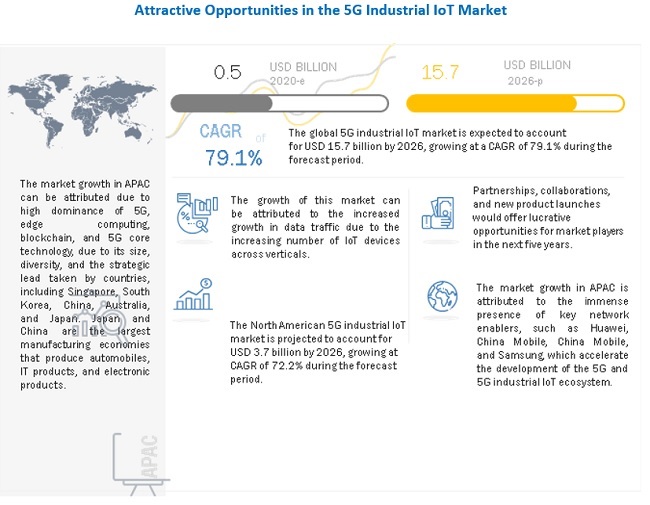

The global 5G Industrial IOT market size is expected to grow from USD 0.5 billion in 2020 to USD 15.7 billion in 2026, at a Compound Annual Growth Rate (CAGR) of 79.1% during the forecast period. The major factors driving the growth of the 5G Industrial IOT market include growth in data traffic due to increasing number of IoT devices across manufacturing industries, increasing demand for high reliability and low latency networks in manufacturing industries, growth in number of M2M connections across manufacturing industries, and rising need of preventive maintenance for critical equipment.

To know about the assumptions considered for the study, Request for Free Sample Report

The COVID-19 pandemic has created significant disruption across every line of businesses, including enterprises, industrial, and government sectors. However, in recent times, with lockdown restrictions getting relaxed in almost every region across the world, businesses in various industry verticals including manufacturing industries, are resuming their operations. The COVID-19 pandemic has forced manufacturing companies to adopt remote working facilities to ensure business continuity. The remote working across widespread geographies demands a high-speed network, such as 5G, for experiencing higher connectivity and improved performance. Further, the manufacturing companies are demanding to switch to predictive analytics-driven processes to streamline their business operations in the most optimized way. In the current scenario, the consumer has become extremely quality conscious. 5G industrial IoT solutions can enhance the analytics process and thus manufacturers can enforce quality checks and thresholds across production lines to get the best output. 5G, due to its higher performance, lower latency, and increased reliability, can provide improved connectivity to IoT-enabled connected assets, as real-time asset data will be increasingly used in the near future to derive actionable insights for the connected equipment, increase productivity, compress costs, and enable intelligent solutions.

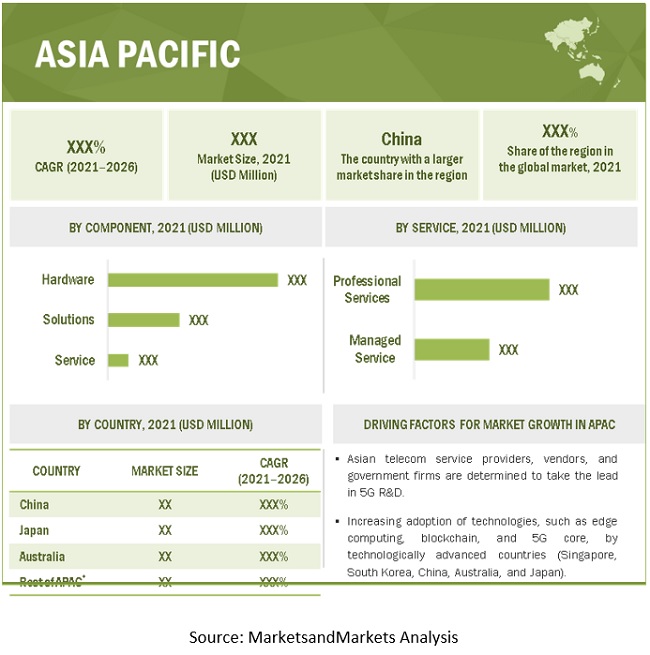

Hardware segment to account for a larger market size during the forecast period

The hardware segment of the 5G industrial IoT includes 5G modules, gateways, sensors, and chips. With the growing demand for 5G industrial IoT, the 5G IoT module acts as one of the major components in the hardware segment of the 5G industrial IoT market. The leading IoT module providers are also exploring how they can position specific products in the market. Both components and module providers are investing in R&D while simultaneously considering the chipsets for specialized applications in the manufacturing operations. In addition to developing 5G modules, suppliers are pursuing several other innovations, such as modifications that decrease device size and strategies for the integration with other modules.

Managed service segment to grow at a higher CAGR during the forecast period

The growth of the managed services segment is expected to be driven by the increased monitoring and security requirements, improved regulatory compliances, enhanced productivity, and improved data integrity while meeting strict Service-Level Agreements (SLAs). Manufacturing companies deploy 5G industrial IoT solutions to manage four elements: products, processes, people, and infrastructure. In manufacturing industries, advanced sensors, control systems, and software applications work together to obtain and share real-time information as finished goods make their way down the production line. Managed Service Providers (MSPs) connect people across all business functions and regions and provide them with relevant information related to intelligent design, operations, and maintenance as well as offer higher quality of services and safety.

Large enterprises, by organization size segment to lead the market during the forecast period

Large enterprises are witnessing an increased need to deploy 5G industrial IoT solutions and services to efficiently manage their large number of assets spread across geographies. The adoption of 5G industrial IoT solutions and services in large enterprises is much high as compared to SMEs. The high adoption is due to the affordability and high economies of scale of large enterprises that enable organizations to leverage 5G industrial solutions and services. The market being at the nascent stage, several big firms are launching 5G modules by having partnerships with telecom operators to deploy services at a faster pace.

Real-time workforce tracking and management segment to grow at a higher CAGR during the forecast period

Real-time workforce tracking and management help manufacturing enterprises streamline their processes and identify, deploy, validate, as well as manage their employees and connect with them in real time. 5G technology has the potential to bring unprecedented levels of change in the workplace as well as workforce management. 5G, along with IoT, can automate workforce management activities, such as scheduling tasks and assigning field resources and equipment to various employees on the respective manufacturing floor. 5G combined with IoT-enabled connected worker solution can bring monitoring capabilities to the next level, making workplaces more efficient, transparent, safe, and productive.

Discrete industries, by end user segment to lead the market during the forecast period

The discrete industries are concerned with the manufacturing and production of distinct units, such as automobiles, furniture, toys, smartphones, and airplanes. The growth of IoT is leading to improvements in discrete industries. In discrete industries, IoT-enabled smart connected products provide a way to increase product functionality and generate additional value for customers. The 5G technology increases the overall bandwidth and allows a massive amount of IoT devices to connect, thus helping discrete manufacturers increase their productivity. 5G industrial IoT solutions are expected to increase the operational efficiency of the discrete manufacturing process by offering higher connectivity among IoT devices.

To know about the assumptions considered for the study, download the pdf brochure

APAC to account for the largest market size during the forecast period

APAC, being an emerging economy, is witnessing dynamic changes in the adoption of new technologies and expected to record the highest market size and CAGR during the forecast period. It is a diversified region that includes a wide range of countries moving toward digital transformation. The region is set to dominate 5G, edge computing, blockchain, and 5G core technology, due to its size, diversity, and the strategic lead taken by countries, including Singapore, South Korea, China, Australia, and Japan. APAC is one of the biggest markets for connected devices. Such a huge number of connected devices requires high-speed and low latency networks, such as 5G. China, Australia, Japan, and South Korea are the prime APAC countries that have started several 5G-related activities. Asian telecom service providers, vendors, and government firms are determined to take the lead in 5G R&D. The region is witnessing dynamic changes in the adoption of new technologies and advancements in manufacturing industries.

Market Dynamics

Driver: Increasing demand for high reliability and low latency networks in manufacturing industries

Ultra-high reliability and low latency are a few of the major factors driving the growth of 5G Industrial IoT market. Latency in computer network refers to the time a data packet takes to travel. Lower latency leads to a higher data transmission rate. The latency of 5G is almost 50 times lower than the current 4G network. The 5G technology is expected to provide a latency of 1 millisecond, whereas, in 4G, the latency rate is 50 milliseconds. Because of this, 5G services would be high in demand for manufacturing applications and connected IoT ecosystems, as these applications and connections need faster and reliable network services. Connectivity plays a crucial role in Industry 4.0. Industrial networks need a stable, secure, reliable, and fast connection to capture and process data in real-time for plant and equipment monitoring. 5G, with low latency and high-reliability attributes, is expected to provide improved connectivity by providing the speed, capacity, and mobility, that manufacturers require for enhanced IoT implementation.

Restraint: High costs required for deployment of 5G network

The transition from 4G to 5G technology would result in huge investments. The costs of 5G infrastructure depend heavily on the required throughput density, periodic interest rate, and base station price. The reduction of these costs is important for effective and ultra-dense small cell deployments. Some have begun to integrate mmWave bands spectrum (28 GHz) into cost modeling heterogeneous networks whereas small cell solutions, such as picocells with mmWave, are deployed in areas of high demand. 5G deployment would require 8–10 times more base stations than 4G and upgrade of the hardware infrastructure by Mobile Network Operators (MNOs). This would result in high capital investments by MNOs. There is a sense of uncertainty among MNOs related to the adoption of 5G. Hence, the huge capital investment required in setting up the infrastructure may act as a restraint to the development of 5G services for industrial IoT.

Opportunity: Rising demand for private 5G network across manufacturing industries

A private 5G network is a local area network that utilizes 5G technology as its communication medium to build a private network. Private 5G networks are referred to as local 5G networks or Mobile Private Networks (MPNs) and offer unified connectivity with numerous advantages and optimized services. In the near future, the private 5G network is expected to become one of the preferred choices, especially for industrial sectors, such as manufacturing. A private network is expected to include all features of 5G public networks, including the reduced latency and higher speeds. A private network delivers several advantages, in terms of efficiency and security, thus various manufacturing organizations and other end users are looking forward to deploying these networks. Private 5G networks have the potential to become the future communication platform of the factory as they will be able to provide increased bandwidth for increased number of connected equipment and the corresponding data being transmitted at the factory floor.

Challenge: Issues related to deployment and coverage of 5G networks

Even though 5G offers significantly high speed and bandwidth, it has a limited range that will require additional infrastructure. 5G antennas can handle more users and data, but they can beam out radio waves over shorter distances. This, in turn, will lead to the installation of extra repeaters to spread waves for an extended range while also maintaining consistent speeds in densely populated regions. Regulations and local authority policies have slowed the deployment of small cells through excessive administrative and financial obligations on operators, thereby reducing investments. Lengthy permitting processes and procuring exercises are among the major constraints for deploying small cells, and the time taken by local authorities to approve planning applications for small cell implementations can take months, resulting in delays. High fees charged by local authorities to utilize street furniture, such as utility poles, are another major challenge faced by companies toward the 5G network deployment.

Market Players

The report includes the study of key players offering 5G Industrial IOT market offerings. It profiles major vendors in the global 5G Industrial IOT market. The major vendors include Qualcomm Technologies, Inc. (Qualcomm), Ericsson (Ericsson), Nokia (Nokia), Huawei Technologies Co., Ltd. (Huawei), Cisco Systems (Cisco), AT&T (AT&T), IBM Corporation (IBM), Microsoft Corporation (Microsoft), Siemens AG (Siemens), Verizon (Verizon), Sierra Wireless (Sierra Wireless), Telefónica S.A. (Telefónica), China Mobile Limited (China Mobile), China Unicom (Hong Kong) Limited (China Unicom), Vodafone (Vodafone), Advantech Co., Ltd. (Advantech), ASOCS (ASOCS), T-Mobile USA, INC (T-Mobile), TELUS (TELUS), Honeywell International Inc. (Honeywell), Intel Corporation (Intel), Bosch.IO GmbH (Bosch.IO), Deutsche Telekom AG (Deutsche Telekom), Telit (Telit), Thales Group (Thales), IDEMIA (IDEMIA), KT Corporation (KT), ABB (ABB), and NTT Data Corporation (NTT Data). The study includes an in-depth competitive analysis of these key players in the 5G Industrial IOT market with their company profiles, recent developments, and key market strategies.

Scope of Report

Report Metric | Details |

Market size available for years | 2020–2026 |

Base year considered | 2020 |

Forecast period | 2021–2026 |

Forecast units | Value (USD Million) |

Segments covered | Component (Hardware, Solutions, Services), Organization Size, Application, End User and Regions. |

Regions covered | North America, Europe, APAC, and RoW |

Companies covered | Qualcomm Technologies, Inc. (US), Ericsson (Sweden), Nokia (Finland), Huawei Technologies Co., Ltd. (China), Cisco Systems (US), AT&T (US), IBM Corporation (US), Microsoft Corporation (US), Siemens AG (Germany), Verizon (US), Sierra Wireless (Canada), Telefónica S.A. (Spain), China Mobile Limited (China), China Unicom (China), Vodafone (UK), Advantech Co., Ltd. (Taiwan), ASOCS (Israel), T-Mobile USA, INC (US), TELUS (Canada), Honeywell International Inc. (US), Intel Corporation (US), Bosch.IO GmbH (Germany), Deutsche Telekom AG (Germany), Telit (UK), Thales Group (France), IDEMIA (France), KT Corporation (South Korea), ABB (Switzerland), and NTT Data Corporation (Japan). |

This research report categorizes the 5G Industrial IoT market to forecast revenues and analyze trends in each of the following submarkets:

Based on Component, the 5G Industrial IoT market has the following segments:

- Hardware

- Solutions

- Services

Based on Organization Size, the market has the following segments:

Based on Application, the 5G Industrial IoT market has the following segments:

- Predictive Maintenance

- Business Process Optimazation

- Asset Tracking and Management

- Logistics and Supply Chain Management

- Real-Time Workforce Tracking and Management

- Automation Control and Management

- Emergency and Incident Management, and Business Communication

Based on End User, the market has the following segments:

- Process Industries

- Discrete Industries

Based on regions, the 5G Industrial IoT market has the following segments:

- North America

- Europe

- APAC

- Rest of World (RoW)

Recent Developments:

- In January 2021, Ericsson and Ooredoo Group signed a five-year strategic 5G agreement for the supply of 5G radio, core, and transport products and solutions, as well as related implementation and integration services.

- In December 2020, Nokia and Thai mobile operator, dtac, part of Telenor Group, came into partnership wherein dtac selected Nokia as its first 5G RAN partner in a three-year deal covering the North and North Eastern regions of Thailand.

- In December 2020, Huawei and Shenyang Institute of Automation of Chinese Academy of Sciences (SIACAS) collaborated to introduce their ‘5G+Industrial Network’ joint innovation center. ‘5G+Industrial Network’ has become crucial for Industry 4.0 and is improving network connectivity and stability, building a new architecture for industrial interconnections, and is backing up next-generation fully connected smart factories.

- In February 2020, Cisco announced advancements to its IoT portfolio that enable service provider partners to offer optimized management of cellular IoT environments and new 5G use cases. New wireless technologies, such as 5G, Wi-Fi 6 will lead to more devices and new advanced IIoT use cases and will give service providers the tools to create competitive cellular IoT offerings for their customers.

- In September 2019, Qualcomm launched a commercial chipset solution combining modem, RF transceiver, and RF front-end, which is named as Qualcomm Snapdragon 5G Modem-RF System. The company allows Original Equipment Manufacturers (OEMs) to quickly develop cutting-edge 5G devices through the solution.

Key Benefits of Buying the Report

The report would provide the market leaders/new entrants in this market with information on the closest approximations of the revenue numbers for the overall 5G INDUSTRIAL IOT market and its subsegments. It would help stakeholders understand the competitive landscape and gain more insights to better position their business and plan suitable go-to-market strategies. It also helps stakeholders understand the pulse of the market and provides them with information on key market drivers, restraints, challenges, and opportunities.